BLOGS > DETAILS

Specifications Demystified: Writing Smarter, Not Harder

2025 Aug 25

Specifications Demystified: Writing Smarter, Not Harder

Specifications might not get the spotlight that renderings or BIM models do, but in practice, they’re what make projects buildable. They’re also one of the most common points of confusion in AEC: What makes a good spec? How do you keep them current? And why does the CSI 3-part format matter so much?

In this post, we’ll unpack the most frequent questions design teams have about specs and highlight strategies to make the process faster, clearer, and less error-prone.

What’s the difference between guide specs and project specs?

A guide specification is a starting template created by a manufacturer or standards body. It covers product details, performance criteria, and execution guidelines in CSI 3-part format, but it’s meant to be edited.

A project specification is tailored to your specific job. It takes that guide spec and adjusts for code requirements, performance goals, and owner preferences.

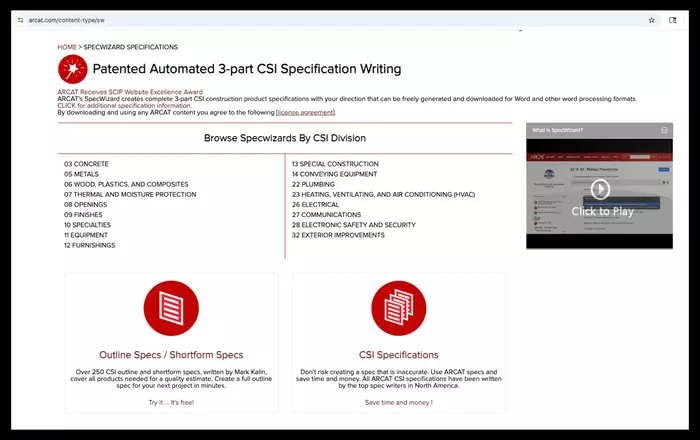

🔗 ARCAT hosts more than 1,000 manufacturer guide specifications, all free and ready to edit - and tools like SpecWizard® can even gene rate a custom project spec based on a few quick product selections.

How do I keep specs up to date?

Outdated specifications are a leading cause of RFIs and change orders. The challenge is that codes, standards, and product lines evolve constantly. The best practice is to:

- Start from manufacturer-hosted specs (not a file saved from three projects ago).

- Check that the version aligns with the latest product cut sheets.

- Use tools that automate updates when product data changes.

🔗 That’s exactly what ARCAT does - specs are maintained by manufacturers, so you’re never pulling from stale content. Browse the ARCAT speci fication library to find current guide specs.

Why does CSI 3-part format matter?

CSI’s MasterFormat and SectionFormat systems are more than just organization. They:

- Make specs searchable across divisions.

- Ensure clarity between Product, Execution, and General requirements.

- Allow contractors, consultants, and owners to find what they need quickly.

Skipping the format often leads to ambiguity - and ambiguity leads to mistakes in the field.

What makes a good specification?

From the design side, a good spec is:

- Clear: no redundancies, no vague instructions.

- Coordinated: matches the drawings and BIM content.

- Compliant: up to date with codes and performance standards.

From the manufacturer side, a good spec is:

- Accurate: reflects the real product line.

- Supported: paired with BIM and CAD so the data stays consistent.

- Accessible: free to view, download, and edit.

Do I really need to write every spec from scratch?

No, and most firms don’t. The smart approach is to leverage guide specs, then customize for your project. Tools like SpecWizard® take this further by automating the editing process. You select the product type, performance options, or finish choices, and the tool generates a project-specific 3-part spec instantly.

This reduces the risk of errors from manual editing and saves hours in coordination.

The Bottom Line

Specs don’t have to be intimidating. At their best, they’re a precise roadmap that keeps everyone - from architect to contractor to owner - on the same page. By starting with accurate guide specs, keeping content current, and leaning on tools that simplify the process, you can spend less time editing and more time designing.

👉 Explore ARCAT’s free specification library or try SpecWizard® to see how much easier specs can be.